Quench Water Hydrocyclone for Coke & Tar Removal. Arya Sasol Olefin Plant, (Licensor Technip) – Design capacity: 2130 m3/h

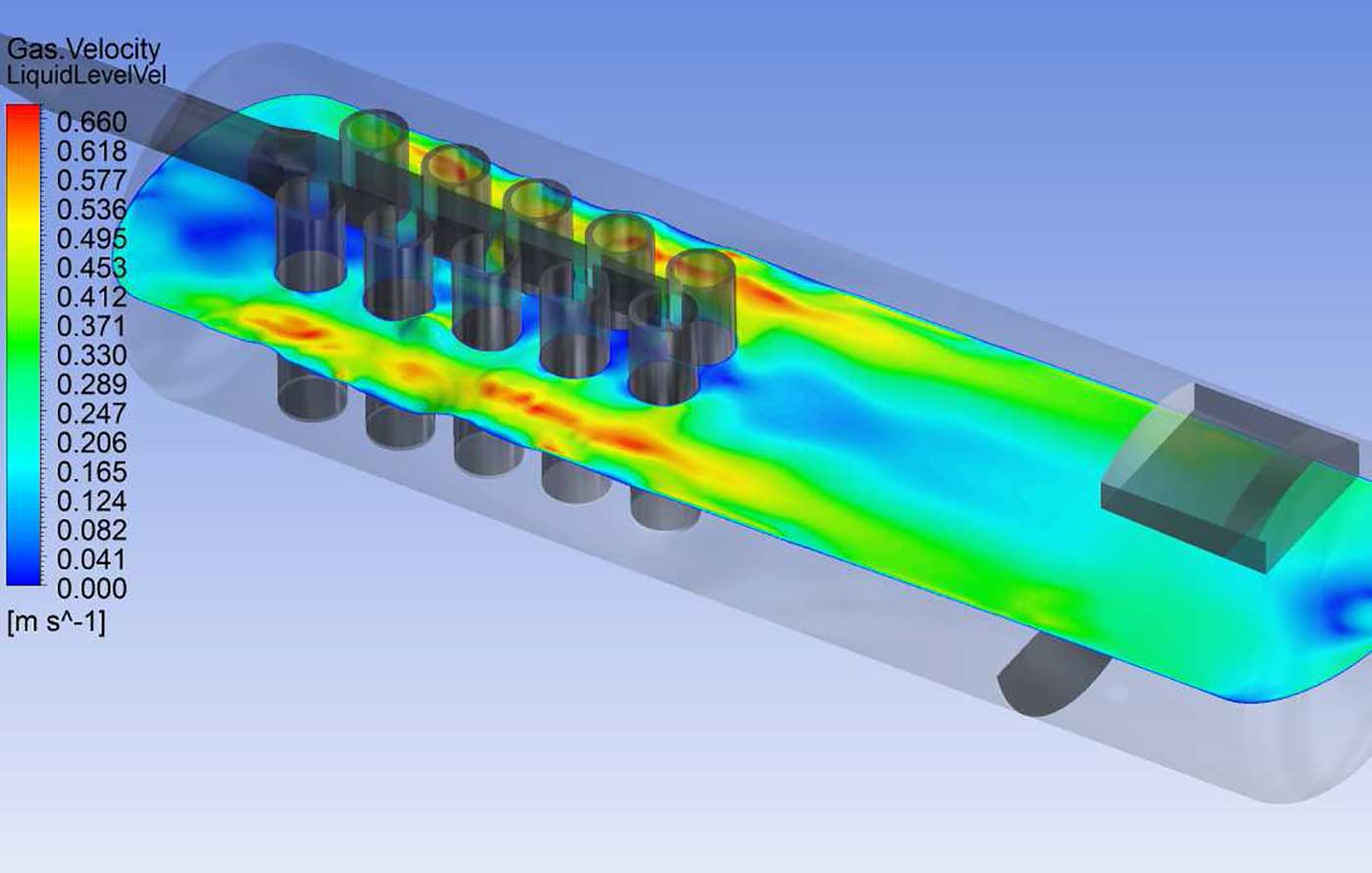

Quench Oil/Water Cyclones

Ehylene is produced by heavier hydrocarbons steam craking process. The high temperature of at the cracker unit causes a coke creation. The coke partcles are removed from the gas phase to the oil phase when oil is used for quenching and can be accumulated there. The very hard coke particles can cause problems at columns trays, heat exchangers and calming points of unit. By fouling of heat exchangers the quench oil temperature in loop will rise up, the production capacity of ethylene unit will decrease and heat exchanges and columns must be cleaned by mechanical way. The quantity, properties and solid particles distribution are not uniform for all operated ethylene plants and they depend on feedstock composition.

Coke particles are removed from cooled gas phase and they remain in the quench oil loop liquid phase. Then it is recommended to remove coke solid particles from liquid phase by installation some separator in this loop.

PETROSAHEL propose a two stage coke and tar filtration . The first stage is coke separation from the main quench oil stream by using hydrocyclones. From this stage (from cyclones bottom) some portion of quench oil enriched by coke is withdrawn and brought to specially design process filter. This is the coke removing systems approved at many ethylene plants over the world.

Coke Removal System (2 Cyclones Type Z600-150 + 2 Settelers Type KS1000). Each of hydrocyclones is designed for Max. flow of 4200 m3/h of quench oil filtration. This system is installed in a Chinese Ethylene plant. (Photo from our Customer)

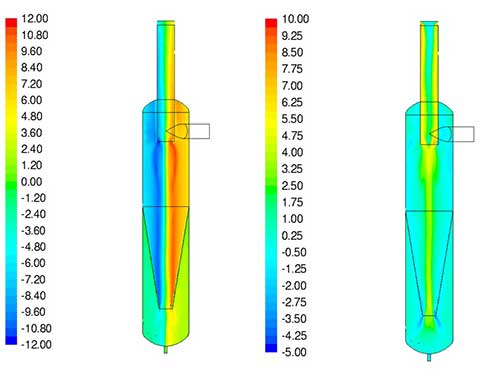

Quench Oil Hydrocyclone Optimization for Dahej Petrochemical, India. The challenge was coping with heavy pyrolysis oil. Capacity: 4690 m3/h (Plant Licensor: Linde)

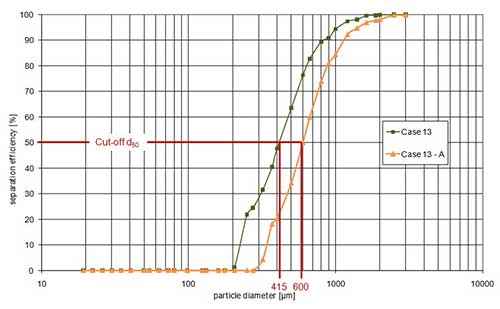

Grade Separation Efficiency Curves: Experimental versus CFD optimization