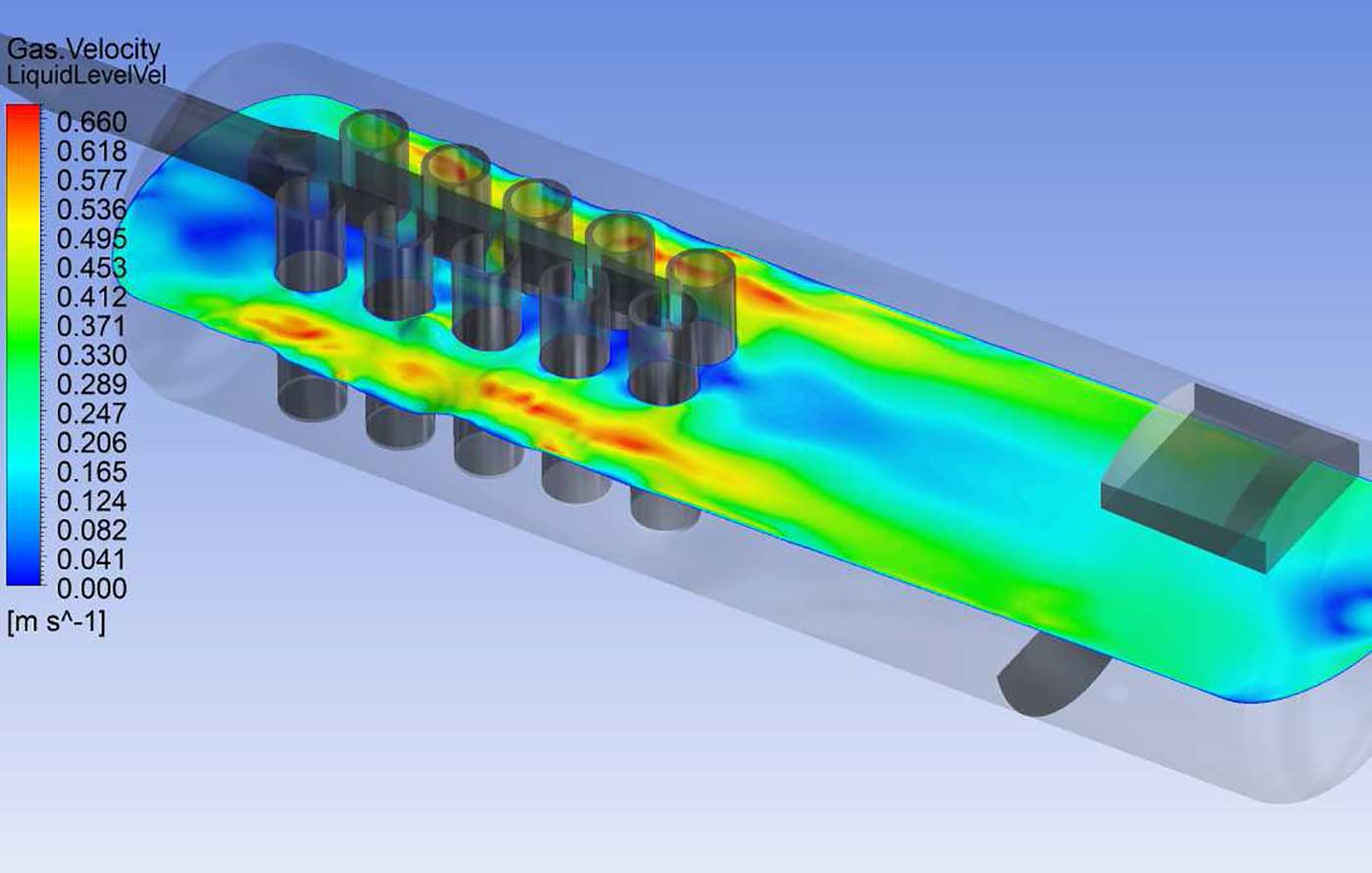

Inlet Cyclone (Vortex Cluster)

Inlet Cyclone

The cyclonic-type inlet device is used to diffuse the momentum of the incoming feed stream and allows for the removal of any bulk liquids and solids that may be present. Depending on the flow rates, more than one cyclone tube may be required to rapidly degas the oil and this allows the use of a shorter oil retention time. Degassing is rapid, and large bubble foam is minimized or eliminated. Without the cyclonic inlet, foam can occupy a considerable volume in the separator. A well-designed cyclonic-type inlet device provide a number of advantages to the operation of a gas/liquid separation and may reduce vessel size. Reversely, a poorly designed inlet cyclone can shear the liquids, cancel out the benefits of the coalescence and possibly making the situation worse.

CFD case study of an Inlet cyclone effect on a multiphase separator performance: