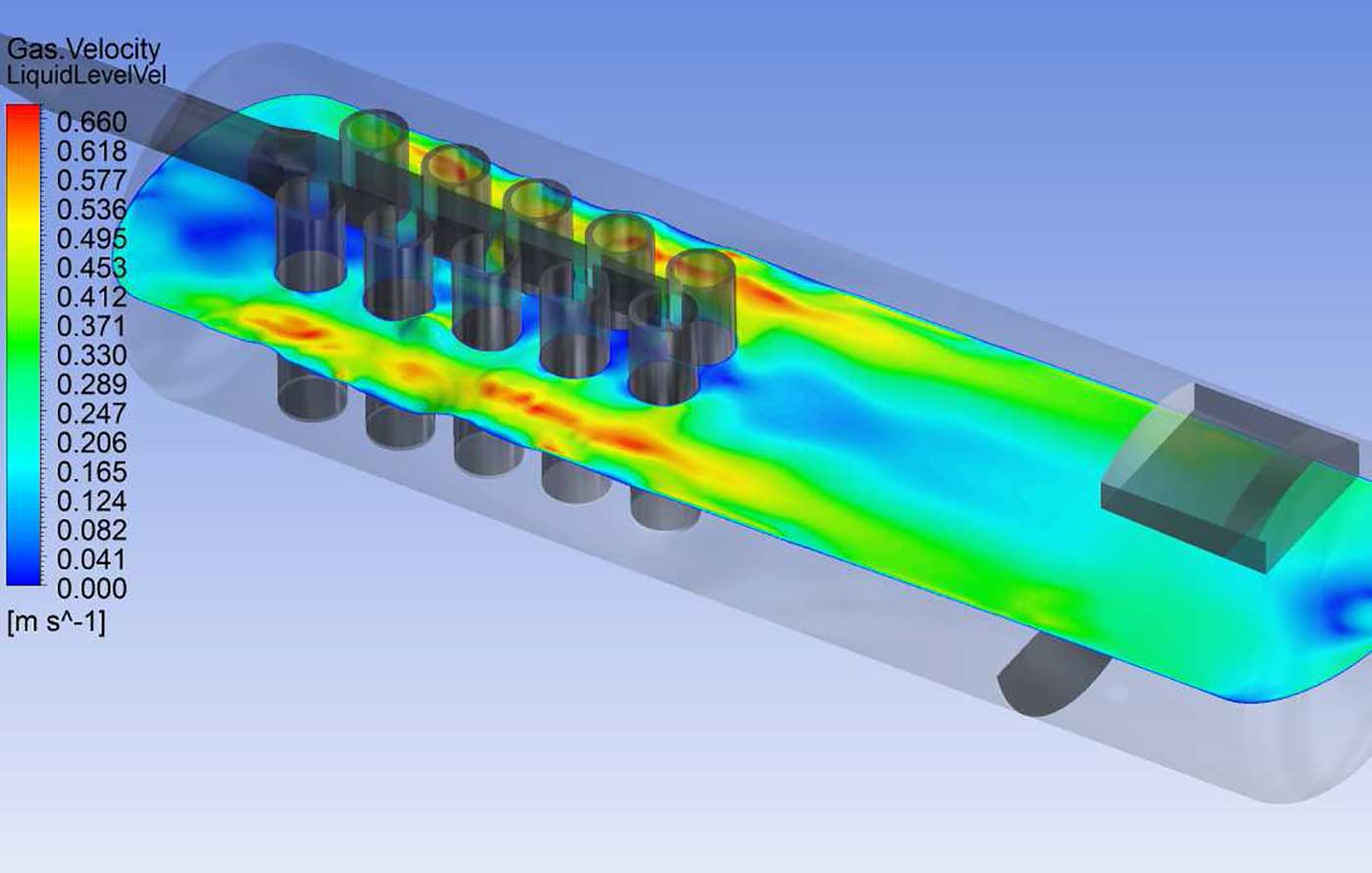

Mechanical-type IGF

Induced Gas Flotation Units

We supply a full range of gas flotation technology including hydraulic and mechanical multi-cell Induced Gas Flotation (IGF) units. Both technologies are reliable for purification of oily process water and industrial wastewater.

Our IGFs, under certain specified conditions, removes up to 95% of insoluble oil and suspended solids from water. However, Removal efficiency is influenced by physical characteristics of the feed stream such as concentration of free oil and suspended solids, temperature, presence of chemicals, and the electrokinetic potential of the water being treated.

IGF system consists of a cylindrical vessel partitioned into several cells each comprises of its dedicated bubble generation system. Bulk water moves in series from one cell to the other by under flow baffles. Depending to hydraulic-type or mechanical-type flotation units, each cell contains eductors, diffusers and gas dispersion devices or motor-driven paddle and associated bubble generation and distribution devices. The flotation assembly uniformly distributes small gas bubbles throughout the cell volume These entrained gas bubbles lift or float contaminants e.g. oil droplets and suspended solids to the surface of the water where they build an unstable foam/froth layer. The foam and oily water froth are then continuously skimmed from liquid surface by overflowing a weir into an oily water collection chamber. This takes place in multiple cells, each one polishing the water more than the previous.

Hydraulic-type IGF