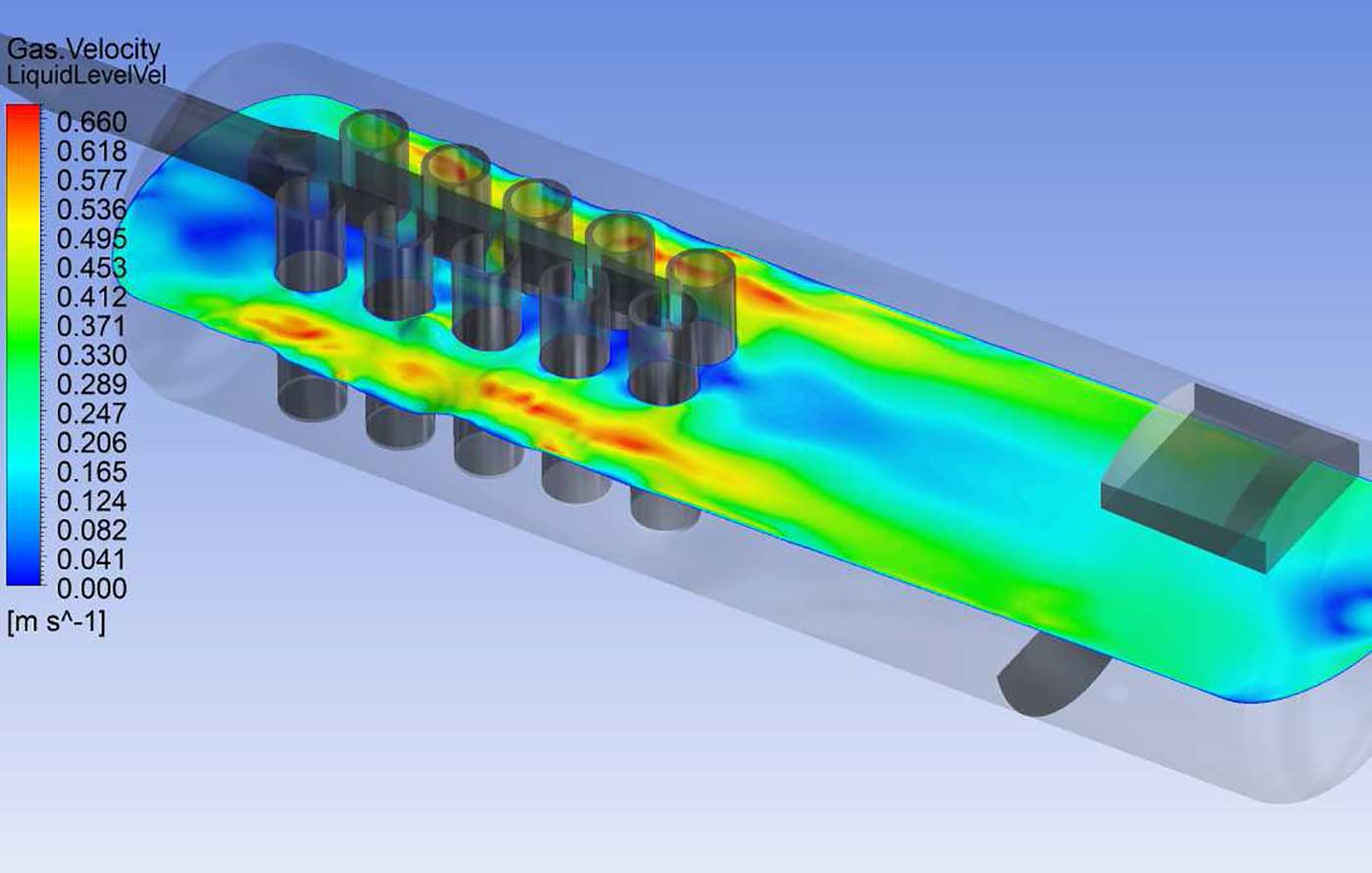

De-oiling hydrocyclones are used to remove the bulk of free oil content from oily water (in general). They are typically one of the first stages in the oily-water and produced water treatment processes to reduce the load on downstream treatment equipment and are usually located downstream of the primary (three-phase or FWKO) separators.

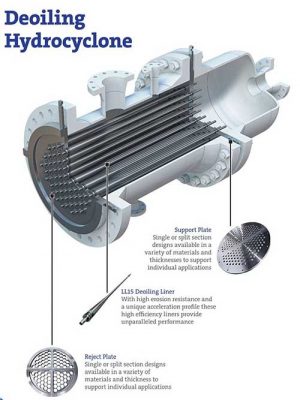

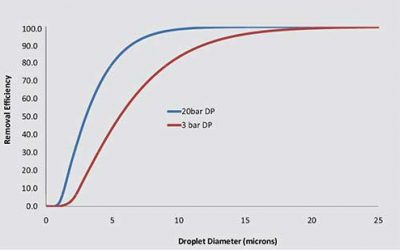

The central feature of our deoiling hydrocyclones is the internal geometry of each liner design, developed to provide high separation efficiency. Our high efficiency LL15 hydrocyclone has been shown to achieve separation performances of more than 99%. It can also handle inlet free oil concentrations of more than 20%. Whether for new projects or as an upgrade to existing vessels, the LL15 hydrocyclone will provide operators with the best performance throughout the widest flow range. It will reduce oil discharge levels (below 10ppm) and minimise operator intervention.