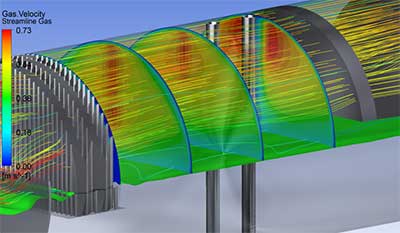

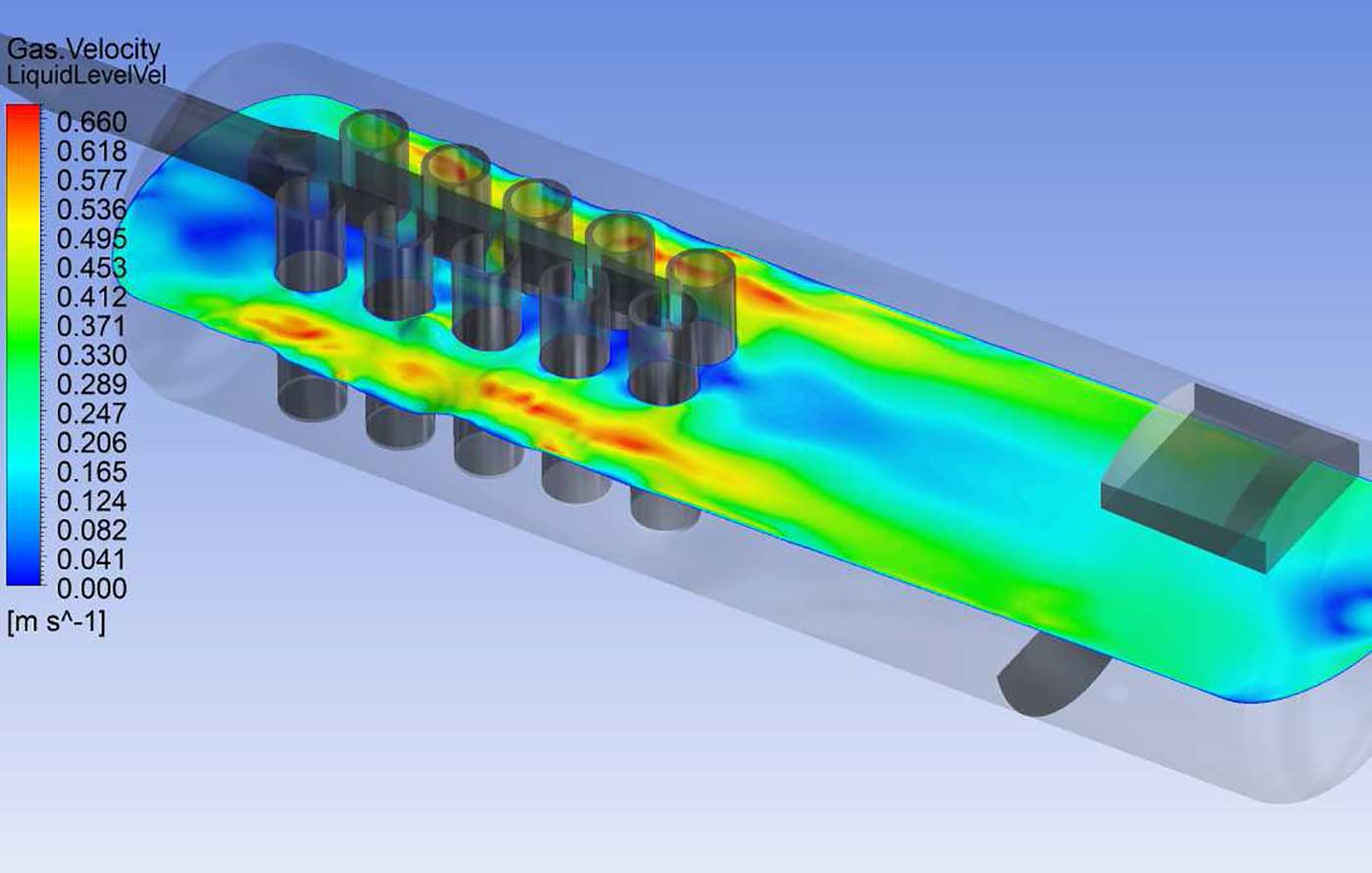

Vane-type Foam Breaker

Foam Breakers

With light gassy crude oils, a separation problem can occur if foams form with flow through the restrictions of a typical separation system. Foaming greatly reduces the capacity of oil/gas separators because a much longer retention time is required to adequately separate a given quantity of foaming crude oil. Oil foam is not stable or long-lasting unless a foaming agent is present in the oil.

When the liquid gravity API is high we use Laminar flow stabilizers to produce essentially laminar flow of the gas, which in turn promotes free-settling of any liquid droplets. However, knowledge of API gravity alone is not sufficient to determine whether or not crude oil will exhibit a serious tendency to foam. For crudes that have a serious tendency to foam, foam breakers can be extremely effective.

CFD case study of a multi-vane foam breaking performance in a multiphase separator: